与外部利益相关方协作是关键。

但行业内的深入协作同样至关重要:对于ICS而言,当成员与同一工厂合作,他们将每月会面,分享审核工具、监控规则和工厂审核结果。ICS 成员如今也会按照国家和主题分享关于风险分析的合并数据。这些各种形式的互助活动都是 ICS 成员之间非竞争性主题,要求成员签署并承诺遵守《行为守则》加以规范。

ICS 行动基于 ICS 所有成员使用的共享工具和通用方法及品牌商对于审核流程的全面掌控。

我们的服务

ICS 方法

工厂手册

共享数据库

在线 CAP 监控

ICS 方法

ICS 审核由成员公司授权并管理。审核的开展是成员的权力之一,以确保对 ICS 工具使用的完全掌控。

ICS 审核只能由 ICS 认证的第三方审核公司开展。

ICS 审核并非一种认证或标签。如工厂被发现重大违规行为,ICS 成员将采用共同监督的方式。

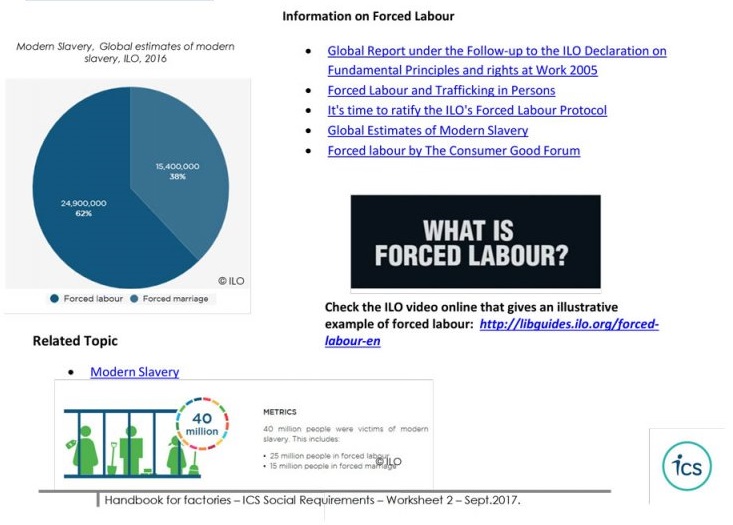

工厂手册

ICS 于2017年详细阐述了面向工厂的《社会责任手册》,帮助工厂更好的了解 ICS 审核的流程、范围和评分系统。该手册还告知被审核工厂审核员将分析的文件清单及面谈和文件审核的抽样范围。《工厂手册》是 ICS 近期为成员的供应工厂及合作伙伴开发的支持性工具及指南,以可持续性地促进工厂合规。(参阅“资源”页面)

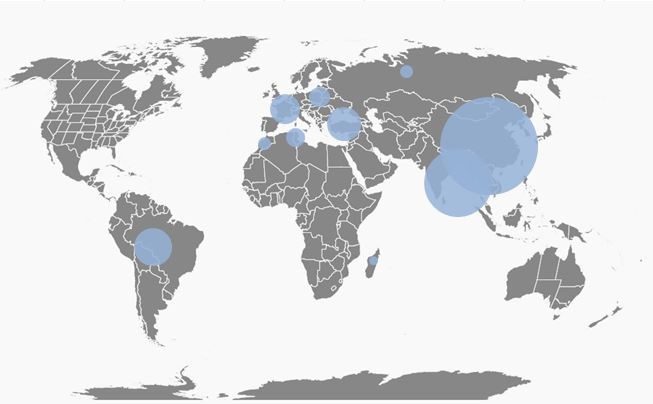

共享数据库

ICS 成员共享 ICS 数据库的数千个工厂和审核信息。ICS 成员只能访问与他们合作工厂的生产地点,以确保机密性。ICS 不是一个采购平台,而是致力于通过分享审核结果和纠正行动计划,以促进品牌商之间采用共同的规则并致力于同样的基本要求。然后,ICS 成员可自由建立自身的公司预览网格。

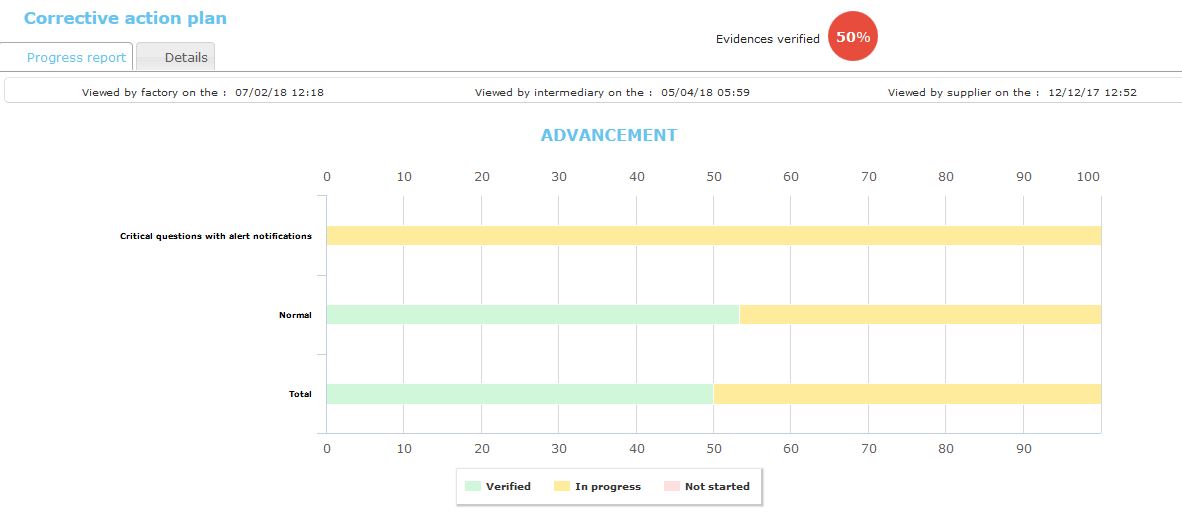

在线 CAP 监控

2017年12月,ICS 在数据库中推出新功能:在线纠正行动计划监控。在此之前,ICS 成员只能针对审核过程中观察到的违规行为做出相对应的纠正行动建议,与供应商和工厂进行单独互动。现在,ICS 在线 CAP 允许已审核工厂和供应链的相关参与方向 ICS 数据库上传证据(例如,更新的许可证,非歧视政策等)。然后,ICS 成员验证并核实 CAP 进展的证据。CAP 进展在相关 ICS 成员之间协调。这项 IT 领域的进步增强了供应链在改善合规性方面的协作水平。